French-Japanese laboratory to study materials under extreme conditions

To strengthen their collaboration in materials science and engineering, the CNRS, Université de Lyon, and Tohoku University are launching an international joint unit (UMI)1 based in Sendai, Japan, on October 4, 2016. Named Engineering Science Lyon – Tohoku for Materials and Systems under Extreme Conditions (ELyTMaX), this new laboratory studies the behavior of materials subject to extreme and complex stress. One of its primary goals is to understand the mechanisms of their deterioration over time, in an effort to better assess their life span.

- 1This new laboratory was created on January 1, 2016.

The research conducted at the ElyTMaX laboratory (CNRS/Université de Lyon/Tohoku University) focuses on the behavior of materials—and the systems they form with other structures—under extreme and complex conditions (pressure, temperature, radiation, or highly corrosive environments).

Three areas of research in particular are being developed:

- Analysis of the evolution of materials used in industry, for example in energy production or transportation. The research is based on both experiments and modeling, within a context of extremely rapid deformation, in order to develop strategies for the conditioning, protection, and healing of surfaces used in industry;

- The study of microsystems used for the conversion of energy, and their resistance to pressure and electric fields. Researchers study new materials and energy conversion systems, using both multi-scale (molecular, macroscopic, etc.) and thermodynamic approaches, in an effort to understand, for example, how the nano-architecture of materials is responsible for the macroscopic effects observed. The study and modeling of physical mechanisms makes it possible to simulate how the microsystems operate, and optimize them prior to their manufacturing;

- The study of the ageing of materials used in biomedical applications, for instance in prostheses or bone substitutes. These materials are subject to particularly high mechanical and dynamic stress, coupled with a physicochemical environment that can accelerate their ageing.

Each of these research areas aims to elucidate the behavior of materials subject to complex stress beginning with their production and implementation, in order to assess their life span. The projects under development rely in particular on the complementarity between French and Japanese researchers, which differs according to area of research. For example, researchers in Lyon have strong expertise in the electrochemical approach of the study of corrosion, while Tohoku University excels in the analysis of corrosion under extreme conditions. This cooperation thus makes it possible to envisage a complete approach of materials science, based on both the development of experimental techniques and the modeling of the physical and physicochemical mechanisms in play.

Tohoku University has been collaborating with research teams in Lyon for more than 30 years, leading to the creation in 2004 of liaison offices at Tohoku University and Université de Lyon, along with numerous academic agreements facilitating the exchange of students and young researchers between the French and Japanese teams. After the creation of an international associated laboratory (LIA) in 2008, the links between the Université de Lyon, Tohoku University, and the CNRS were further strengthened in 2016 with the creation of this international joint unit, which is directed by Kazuhiro Ogawa (Tohoku University) and Jean-Yves Cavaillé (INSA Lyon). Moreover, ELyTMaX hopes to act as an intermediary between the newly-created Fédération ingénierie Lyon Saint-Etienne and the engineering developed at Tohoku University.

This laboratory is the first UMI to be created with a COMUE2

, and the first to study structural materials. Based in Sendai, ELyTMaX is also the first Japanese UMI to be located outside of the Kanto region of Tokyo. It is the primary international structure of Tohoku University, which sees cooperation with French researchers as a privileged means of strengthening its collaboration with Europe.

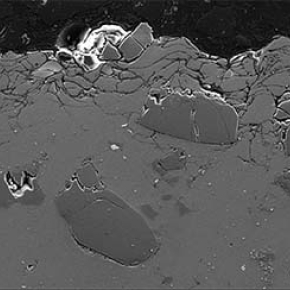

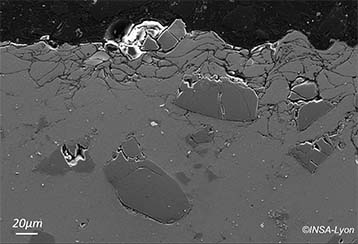

Spread of corrosion in a coating obtained by "Cold spray".

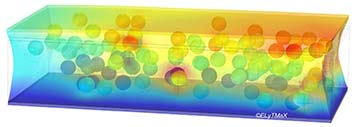

Deformation of heterogeneous materials subject to electromagnetic fields.

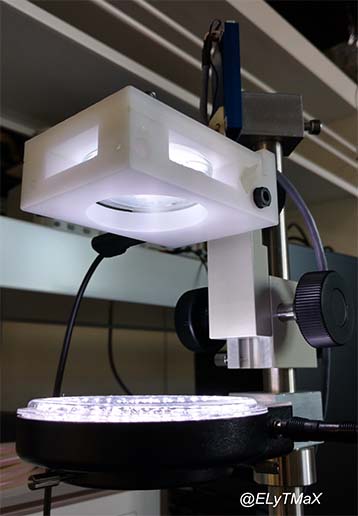

Study of the physical mechanisms at work in smart materials.

Thick deposit of copper (between 50 to 60 mm) obtained by "Cold spray." The deposited copper is machinable: holes for screws, flanges, etc.

- 2The Université de Lyon, which notably includes: the Université Claude Bernard Lyon 1, Université Lumière Lyon 2, Université Jean Moulin Lyon 3, Université Jean Monnet Saint-Etienne, Ecole normale supérieure de Lyon, Ecole centrale de Lyon, INSA Lyon, Sciences Po Lyon, VetAgro Sup, ENTPE, ENISE and the CNRS.